We couldn’t help but look at some more Mg-Zn alloys since our last paper. In particular, we have been looking at what happens to the nanostructure when the alloy undergoes “high-pressure torsion”.

One way to improve metal alloy properties is by reducing the size of the crystalline grains in the material. Such a smaller grain size can, for example, increase the yield stress and ductility.

To drastically reduce the grain size, the alloy can be pushed through an angle-shaped die (called “equal-channel angular extrusion”), or by pressing and twisting pellets of the alloy (the aforementioned high-pressure torsion (HPT)).

So far, it was assumed that no precipitation occurs during HPT processing of Mg-Zn alloys, i.e. that we do not get small crystal phases of Mg-Zn separating out of the magnesium matrix. When we were checking this with SAXS (using Chromium radiation back then, which is a pain to work with), we saw that there actually is something going on.

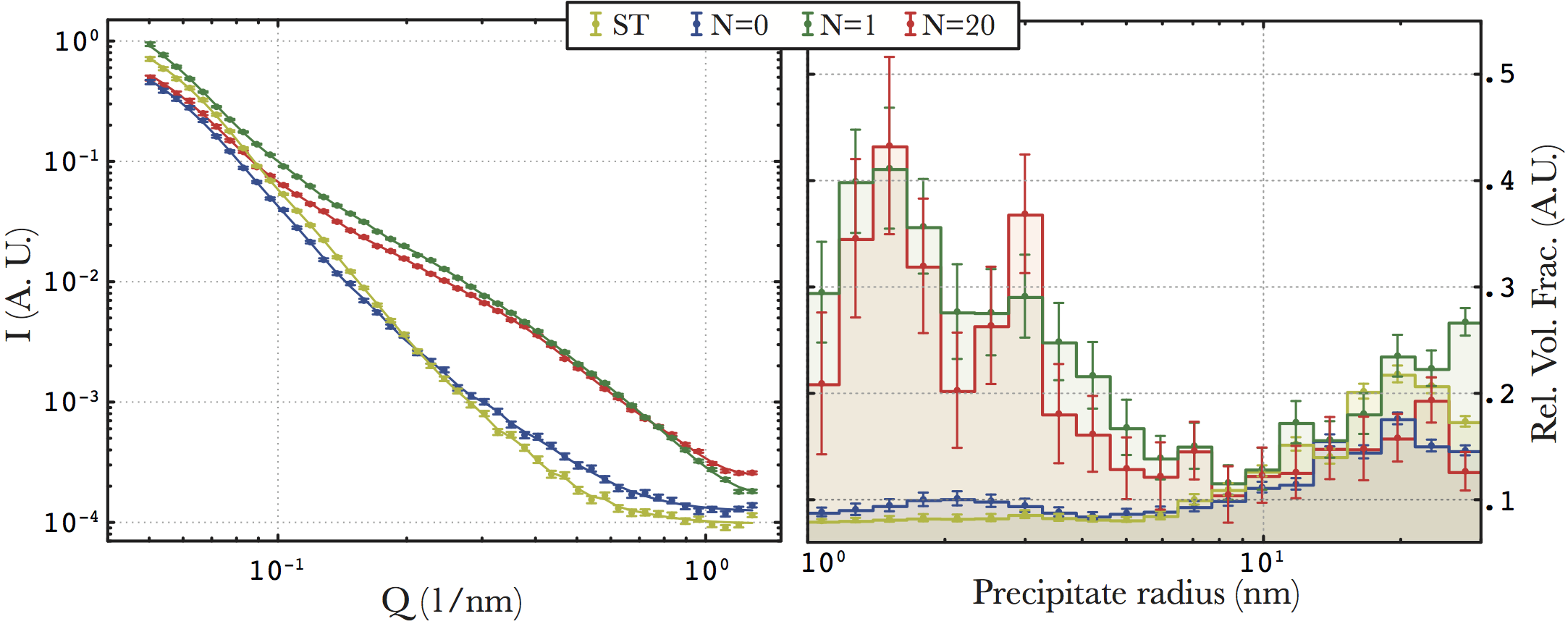

We noticed that the scattering signal changes when the material is compressed (but not rotated), and then changes again when it is rotated once. Continue rotation for a while, however, and the scattering signal remains largely unchanged (Figure 1).

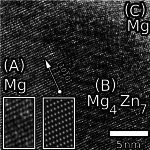

Cue HRTEM investigations, and indeed, in the twisty mess left by the HPT process are small precipitates. Thanks to Julian’s skills and perseverance, the crystal structure was identified as Mg4Zn7 and MgZn2 crystals of a wide variety of shapes (f.ex. as shown in Figure 2, more available in the arXiv paper).

Given the wide variety of shapes, we chose to characterise general precipitate dimensions assuming a spherical shape of the scatterers. When we do this, we see that there is a very large increase of precipitates with radii from 3-5 nm after HPT processing.

This initial research prompted us to do much more on this topic, which we hope to publish about soon. We tried publishing these initial results in Scripta Materialia, but unfortunately it was not found interesting enough by the referees. We did, however, put it up on arXiv (arXiv:1407.6146), from where you can read it freely.

As always, comments are very welcome!

Leave a Reply